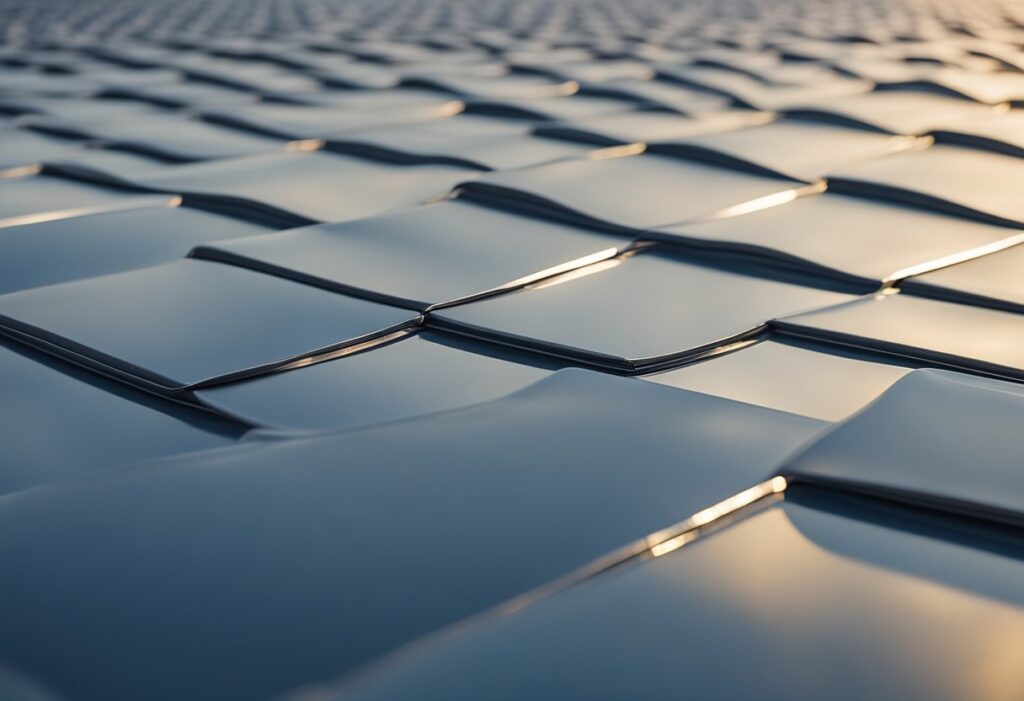

Single ply roofing membrane is a type of roofing system that has become increasingly popular in recent years. It is a lightweight, cost-effective, and eco-friendly alternative to traditional roofing systems. Single ply roofing membranes are made from a single layer of thermoplastic or thermoset membrane, which is held in place by mechanical fasteners, adhesives, or ballast.

There are several types of single ply roofing membrane available, each with its own unique features and benefits. TPO, PVC, PVC-KEE, and EPDM are the most commonly used single ply roofing membranes. TPO and PVC are thermoplastic membranes, while EPDM is a thermoset membrane. PVC-KEE is a hybrid membrane that combines the benefits of both thermoplastic and thermoset membranes. Each membrane type has its own set of manufacturing, installation, and performance characteristics, making it important to choose the right system for your roofing project.

Types of Single Ply Roofing Membranes

Single ply roofing membranes are commonly used in commercial roofing applications due to their durability, energy efficiency, and ease of installation. There are three main types of single ply roofing membranes: thermoplastic, thermoset, and modified bitumen.

Thermoplastic Membranes

Thermoplastic membranes are made from materials such as TPO (thermoplastic olefin) and PVC (polyvinyl chloride). These membranes are highly reflective, which helps to reduce energy costs by reflecting heat away from the building. They are also resistant to UV radiation, chemicals, and punctures, making them a popular choice for commercial roofing applications.

Thermoset Membranes

Thermoset membranes are made from materials such as EPDM (ethylene propylene diene terpolymer) and CSPE (chlorosulfonated polyethylene). These membranes are highly durable and resistant to weathering, ozone, and abrasion. They are also highly flexible, which allows them to conform to the shape of the roof.

Modified Bitumen

Modified bitumen roofing membranes are made from asphalt and rubber modifiers. These membranes are highly durable and resistant to weathering, punctures, and tears. They are also highly flexible, which allows them to conform to the shape of the roof. Modified bitumen membranes can be installed using a variety of methods, including torch-applied, cold-applied, and self-adhering.

Overall, each type of single ply roofing membrane has its own unique characteristics and advantages. It is important to consider factors such as climate, building design, and budget when selecting the best type of single ply roofing membrane for a particular application.

Installation Techniques

Single-ply roofing membranes are installed using one of three techniques: mechanically attached systems, fully adhered systems, and ballasted roofing systems.

Mechanically Attached Systems

Mechanically attached systems involve securing the single-ply membrane to the roof deck using mechanical fasteners such as screws or nails. This technique is typically used for roofs with a slope of less than 2:12. Mechanically attached systems are quick to install and require less labor than fully adhered systems. However, they are not recommended for roofs in areas with high winds or extreme weather conditions.

Fully Adhered Systems

Fully adhered systems involve gluing the single-ply membrane to the roof deck using adhesive. This technique is typically used for roofs with a slope greater than 2:12. Fully adhered systems provide excellent wind uplift resistance and are ideal for roofs in areas with high winds or extreme weather conditions. However, they require more labor and time to install than mechanically attached systems.

Ballasted Roofing Systems

Ballasted roofing systems involve placing a layer of ballast, such as gravel or pavers, on top of the single-ply membrane to hold it in place. This technique is typically used for roofs with a slope greater than 1:12. Ballasted roofing systems are quick and easy to install, require minimal labor, and provide excellent wind uplift resistance. However, they are not recommended for roofs in areas with high winds or extreme weather conditions as the ballast can become dislodged and cause damage.

Overall, the installation technique used for single-ply roofing membranes depends on the slope of the roof, the location of the building, and the weather conditions in the area. It is important to consult with a roofing professional to determine the best installation technique for your specific needs.

Advantages and Disadvantages

Durability and Performance

Single-ply roofing membranes are highly durable and can withstand extreme weather conditions. They are resistant to punctures, tears, and impact damage. They also have high resistance to UV radiation and are less prone to cracking and peeling. Single-ply roofing membranes can last for up to 30 years with proper maintenance, making them a long-term investment for building owners.

Cost Considerations

Single-ply roofing membranes are cost-effective compared to traditional roofing systems. They are lightweight, which means they require less structural support, reducing installation costs. They are also easy to install, which reduces labor costs. Single-ply roofing membranes have a longer lifespan than traditional roofing systems, which means building owners can save money on replacement costs in the long run.

Maintenance and Repair

Single-ply roofing membranes require minimal maintenance and repair. They are easy to clean and can be washed with a mild detergent and water. Repairs are also easy to make, and damaged sections can be easily replaced without having to replace the entire roof. However, building owners should ensure that maintenance and repairs are carried out by experienced professionals to ensure the longevity of the roofing system.

While single-ply roofing membranes offer many advantages, they also have some disadvantages. For example, they may not be suitable for buildings with heavy foot traffic or for areas with extreme weather conditions. Additionally, single-ply roofing membranes may not be suitable for buildings with complex roof designs, as they may require additional seams and adhesives, which can increase the risk of leaks. Building owners should carefully consider these factors before choosing a single-ply roofing membrane for their building.

Environmental Impact and Sustainability

Single-ply roofing membranes have gained popularity in recent years due to their environmental impact and sustainability. They are considered to be a more eco-friendly option compared to traditional roofing systems.

Energy Efficiency

One of the key benefits of single-ply roofing membranes is their energy efficiency. They can reflect sunlight and reduce the amount of heat that is absorbed by the building, which can help reduce cooling costs. This is especially important in areas with hot climates where cooling costs can be a significant expense.

Recyclability and Eco-Friendly Materials

Single-ply roofing membranes are made from recyclable materials such as PVC, TPO, and EPDM. These materials are considered to be eco-friendly because they can be recycled and reused, reducing the amount of waste that ends up in landfills.

Moreover, some single-ply roofing membranes are made with eco-friendly materials such as bio-based polymers. These materials are made from renewable resources and are biodegradable, making them even more environmentally friendly.

In addition, single-ply roofing membranes can also be designed to be resistant to UV rays, chemicals, and other environmental factors, which can extend their lifespan and reduce the need for replacements. This can further reduce the environmental impact of roofing systems.

Overall, single-ply roofing membranes offer a number of benefits in terms of environmental impact and sustainability. They are energy-efficient, made from recyclable materials, and can be designed to be resistant to environmental factors, making them a more eco-friendly option compared to traditional roofing systems.