Metal flat roofs are a popular choice for homeowners and businesses alike due to their durability, longevity, and low maintenance requirements. Metal roofs are made from a variety of materials, including aluminum, steel, and copper. They can be installed on both residential and commercial buildings and are available in a range of colors and styles to suit any aesthetic.

One of the main advantages of metal flat roofs is their longevity. When installed properly, a metal roof can last up to 50 years or more, which is significantly longer than other roofing materials such as asphalt shingles. Additionally, metal roofs are resistant to fire, insects, and rot, making them a great choice for areas with extreme weather conditions. Metal roofs are also low maintenance, requiring only occasional cleaning to remove debris and dirt.

While metal flat roofs can be more expensive than other roofing materials, their longevity and durability make them a cost-effective choice in the long run. They are also energy-efficient, reflecting heat from the sun and reducing cooling costs during the summer months. Overall, metal flat roofs are a reliable and long-lasting choice for any building owner looking for a low-maintenance, durable, and energy-efficient roofing solution.

Types of Metal Flat Roofs

Metal flat roofs are a popular choice for commercial and residential buildings due to their durability, low maintenance, and energy efficiency. There are several types of metal flat roofs available in the market, each with its own advantages and disadvantages. In this section, we will discuss the three most common types of metal flat roofs.

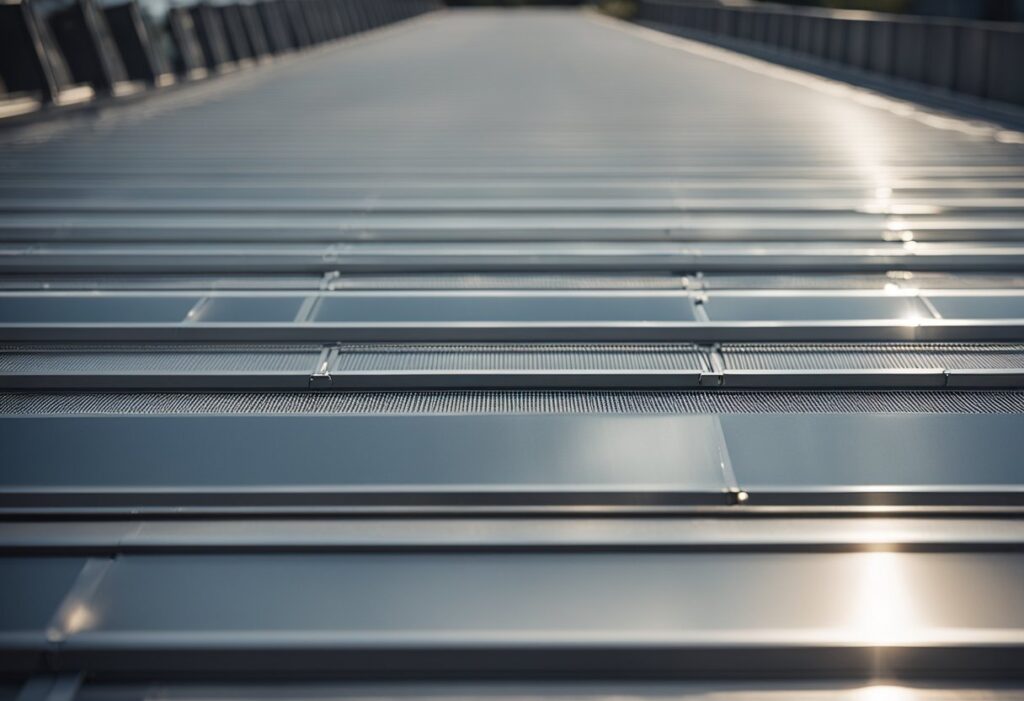

Standing Seam Metal Roofs

Standing seam metal roofs are a popular choice for flat roofs due to their sleek and modern design. The panels are installed vertically and connected with raised seams that run the length of the roof. This design provides excellent water resistance and prevents leaks. Standing seam metal roofs are available in a wide range of materials, including steel, aluminum, and copper. They are also available in a variety of colors and finishes, making them a versatile choice for any building.

Metal Roofing Panels

Metal roofing panels are another popular choice for flat roofs due to their affordability and ease of installation. These panels are available in a wide range of materials, including steel, aluminum, and copper. They are also available in a variety of profiles, including corrugated, ribbed, and flat. Metal roofing panels are lightweight, making them easy to install. They are also highly durable and resistant to weather damage, making them a popular choice for commercial buildings.

Copper and Zinc Flat Roofs

Copper and zinc flat roofs are a popular choice for high-end residential and commercial buildings due to their durability and aesthetic appeal. These roofs are made of copper or zinc sheets that are installed over a flat roof membrane. Copper and zinc flat roofs are highly durable and resistant to weather damage. They also develop a natural patina over time, which gives them a unique and attractive appearance.

In conclusion, metal flat roofs are a durable, low maintenance, and energy-efficient choice for commercial and residential buildings. Standing seam metal roofs, metal roofing panels, and copper and zinc flat roofs are three of the most common types of metal flat roofs available in the market. Each type has its own advantages and disadvantages, so it is important to choose the right type of metal flat roof for your building.

Installation Process

When it comes to installing a metal flat roof, there are several steps that need to be followed to ensure a successful installation. These steps include substrate preparation, insulation and ventilation, metal panel installation, and seaming and finishing.

Substrate Preparation

Before installing a metal flat roof, it is important to prepare the substrate properly. This involves removing any existing roofing material, cleaning the surface, and ensuring that the substrate is level. Any damaged or rotten areas should be repaired or replaced.

Insulation and Ventilation

Insulation and ventilation are important components of a metal flat roof installation. Proper insulation helps to reduce heat loss and gain, while ventilation helps to prevent moisture buildup. Insulation can be installed above or below the roof deck, while ventilation can be achieved through the use of vents or fans.

Metal Panel Installation

Once the substrate has been prepared and insulation and ventilation have been addressed, it is time to install the metal panels. The panels should be installed according to the manufacturer’s instructions, with careful attention paid to the placement of fasteners and the alignment of seams. It is important to use the correct tools and equipment to ensure a secure and accurate installation.

Seaming and Finishing

After the metal panels have been installed, the seams must be sealed and finished. This involves using a seaming tool to join the panels together and applying sealant to prevent leaks. The roof should be inspected carefully to ensure that all seams and joints are properly sealed and that the roof is watertight.

In summary, installing a metal flat roof requires careful attention to detail and a thorough understanding of the installation process. By following the steps outlined above, a successful installation can be achieved, providing a durable and long-lasting roofing solution.

Benefits of Metal Flat Roofs

Metal flat roofs are becoming increasingly popular in the roofing industry. They offer a range of benefits, including durability, energy efficiency, and low maintenance. In this section, we will explore these benefits in more detail.

Durability

One of the main benefits of metal flat roofs is their durability. Metal roofs are known for their ability to withstand harsh weather conditions such as heavy rain, snow, and hail. They are also resistant to fire, mildew, and pests. Metal roofs can last up to 50 years or more with proper maintenance, which is significantly longer than traditional asphalt shingle roofs.

Energy Efficiency

Metal flat roofs are also known for their energy efficiency. They reflect solar energy, which helps to keep the building cool and reduces energy costs. According to Architectural Digest, metal roofs can save homeowners up to 40% in energy costs. Metal roofs are also recyclable, which makes them an eco-friendly option.

Low Maintenance

Another benefit of metal flat roofs is their low maintenance requirements. Unlike traditional asphalt shingle roofs, metal roofs do not require frequent repairs or replacements. They are resistant to rust and corrosion, which helps to extend their lifespan. Metal roofs are also easy to clean and maintain, which saves time and money in the long run.

In summary, metal flat roofs offer a range of benefits, including durability, energy efficiency, and low maintenance. These benefits make metal roofs a popular choice for homeowners and business owners alike.

Common Challenges and Solutions

When it comes to metal flat roofs, there are some common challenges that property owners and contractors face. However, with proper planning and installation, these challenges can be overcome. The following subsections explore some of the most common challenges and solutions for metal flat roofs.

Thermal Movement

One of the challenges of metal flat roofs is thermal movement. Metal expands and contracts with temperature changes, which can cause the roof to buckle or warp. To prevent this, contractors should install a system that allows for thermal movement. This can include using clips to secure the metal panels to the roof deck, rather than screwing them down tightly. Contractors should also ensure that the roof deck is level and that there is enough space for the metal to move without causing damage.

Corrosion Resistance

Corrosion is another common challenge for metal flat roofs, especially in areas with high humidity or salt content in the air. Over time, the protective coating on the metal surface can deteriorate, leaving it vulnerable to rust. To prevent corrosion, contractors should use high-quality metal that is designed for outdoor use. They should also ensure that the metal is properly coated and that there are no gaps or holes in the coating that could allow moisture to seep in.

Waterproofing

Waterproofing is essential for any flat roof, including metal flat roofs. Without proper waterproofing, water can seep into the building and cause damage to the interior. To ensure that the roof is waterproof, contractors should use a high-quality underlayment and flashing. They should also ensure that there are no gaps or holes in the metal panels that could allow water to seep in. Regular inspections and maintenance can also help prevent water damage.

In conclusion, metal flat roofs offer many benefits, but they also come with some challenges. By addressing thermal movement, corrosion resistance, and waterproofing, contractors can ensure that the roof is durable and long-lasting.

Maintenance and Repair

Routine Inspection

To ensure the longevity and durability of a metal flat roof, routine inspections should be conducted at least once a year. These inspections can identify any potential issues before they become serious or create failures in the system. During the inspection, it’s important to look for signs of damage such as dents, scuffs, scratches, and degradation. Additionally, it’s crucial to check for signs of galvanic corrosion, which can occur when two different metals come into contact with each other.

Cleaning and Preventative Maintenance

Cleaning and preventative maintenance are important to keep a metal flat roof in good condition. Regular cleaning can prevent debris from accumulating and causing damage to the roof. It’s recommended to clean the roof at least twice a year. During cleaning, it’s important to remove any debris, dirt, or leaves that have accumulated on the roof. Additionally, it’s important to check the gutters and downspouts for any blockages.

Preventative maintenance can also help extend the lifespan of a metal flat roof. This can include applying protective coatings, such as paint or sealant, to prevent rust and corrosion. It’s also important to ensure that any penetrations, such as vents or pipes, are properly sealed to prevent water from entering the roof system.

Repair Techniques

If damage is identified during routine inspections, it’s important to address it promptly to prevent further damage. Repair techniques for metal flat roofs can vary depending on the type of damage. For minor damage, such as small dents or scratches, a metal roof repair kit can be used to repair the damage. For more significant damage, such as punctures or tears, it may be necessary to replace the damaged section of the roof.

It’s important to note that repairs should only be conducted by a professional with experience in repairing metal flat roofs. Attempting to repair the roof without proper knowledge and experience can result in further damage and potentially costly repairs.